Taiwanese oolong tea, celebrated for its complex flavors and aromatic depth, is a testament to the island’s rich tea-making heritage. Crafted primarily in the misty high mountain regions, this semi-fermented tea reflects a meticulous process honed over centuries. Let’s delve into the seven essential steps that transform fresh tea leaves into the exquisite oolong teas revered worldwide.

Step 1: The Art of Handpicking

The journey begins with handpicking, a labor-intensive practice that selects the finest leaves. Skilled pickers choose “one heart with two or three leaves”—the tender bud and young adjacent leaves—ensuring optimal quality. This gentle technique, prevalent in Taiwan’s steep tea gardens, preserves leaf integrity, laying the foundation for the tea’s future flavor and character.

Step 2: The Transformation of Sun-Withering

Exposed to Taiwan’s gentle sunlight, freshly picked leaves undergo sun-withering. Spread on bamboo trays or cloths, they lose moisture slowly, initiating oxidation. This natural process softens the leaves, shifts their color from green to a darker shade, and releases initial aromas, setting the stage for the tea’s unique profile shaped by the island’s climate.

Step 3: The Precision of Indoor Withering and Rolling

Inside controlled environments, the withering continues with indoor processing. Leaves undergo refined oxidation, their aromas deepening as moisture evaporates. Rolling, often integrated here, gently bruises the leaf edges, allowing air to penetrate and distribute moisture evenly. This step crafts the mellow sweetness and floral notes central to oolong’s semi-fermented identity.

Step 4: The Critical Panning Process

Panning, or “kill-green,” halts oxidation at a precise point, a pivotal moment in oolong production. Using high heat—traditionally by hand over woks, now often with machines—enzymes are deactivated, fixing the fermentation level. This technique, a cornerstone of Taiwanese craftsmanship, preserves the tea’s delicate balance of flavor and fragrance.

Step 5: The Skill of Rolling

After panning, the softened leaves are rolled to refine their form and enhance flavor. Through a blend of manual twisting and mechanical pressure, the leaves’ structure breaks, releasing juices that coat their surface. This process improves the tea’s infusion quality, enriching the brew’s depth and allowing the full expression of oolong’s complexity.

Step 6: The Craft of Cloth Rolling

Cloth rolling shapes oolong into its distinctive semi-spherical or spherical forms, a hallmark of Taiwanese artistry. This technique molds the leaves with repeated effort, creating elegant shapes that reduce volume, aid storage, and intensify flavor. The tighter the roll, the more refined the tea, showcasing the patience and skill of the artisans.

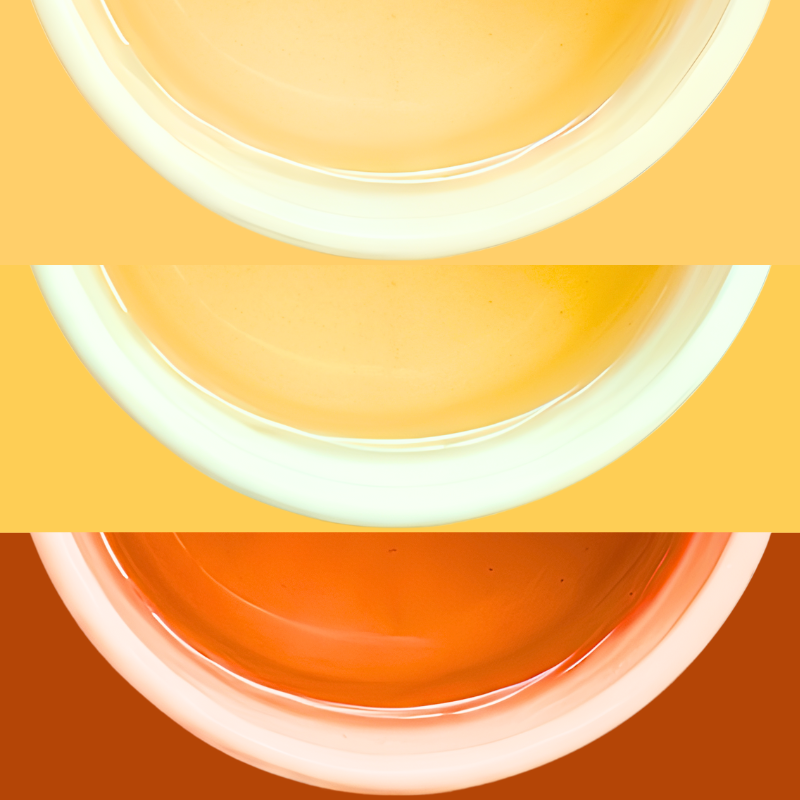

Step 7: Drying to Preserve Excellence

The final step, drying, locks in the tea’s flavor for longevity. Leaves are machine-dried to reduce moisture below 4%, halting fermentation and producing “raw tea” (primary processed tea). This careful dehydration ensures stability, preserving the tea’s aroma and taste, ready for further refinement or immediate enjoyment.

The Essence of Taiwanese Oolong

These seven steps embody the dedication and expertise of Taiwanese tea makers, blending tradition with innovation. From the high mountains to your cup, this process highlights the craftsmanship that makes Taiwanese oolong a global treasure. Learn more about this art and explore tea offerings at formosabrew.com.